Phase 1

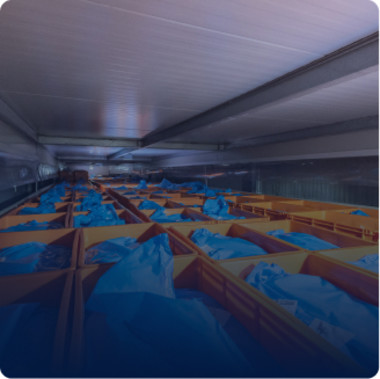

Preparation and set-up of the tunnel after careful analysis of the time required for proper freezing according to the type of product.

SERVICES OF

We firmly believe that maintaining product quality is a fundamental prerogative for those who work in the food industry. For this reason, in 2014 we invested

significant resources in an innovative freezer tunnel: a technological solution that freezes food through a flash freezing system, keeping intact all the organoleptic properties.

Preparation and set-up of the tunnel after careful analysis of the time required for proper freezing according to the type of product.

Definition of time and temperature metrics based on the data collected during the analysis phase, and start-up of the freezer tunnel.

When the cycle is complete, the tunnel is turned off and the stored product is checked and analysed.

The entire flash freezing phase avoids the breakage of product cells by excessively large ice crystals: during defrosting, fluid loss from meat, fish, fruits and vegetables will not occur. Thanks to rapid freezing, meat, fish, fruits and vegetables will preserve their quality and organoleptic properties. For the customer, flash freezing means a considerable reduction of time, efficiency maximisation throughout the process, and the guarantee of a genuine and healthy product.

Kg frozen per year

Cycles carried out

Number of hours of use

Kg frozen per year

Cycles carried out

Number of hours of use