27th January 2025

Shuttle racking system

Index

What Is Shuttle Racking?

Advantages of Shuttle Racking

How to Integrate a Shuttle Racking System into Your Warehouse

What Is Shuttle Racking?

Definition and Use

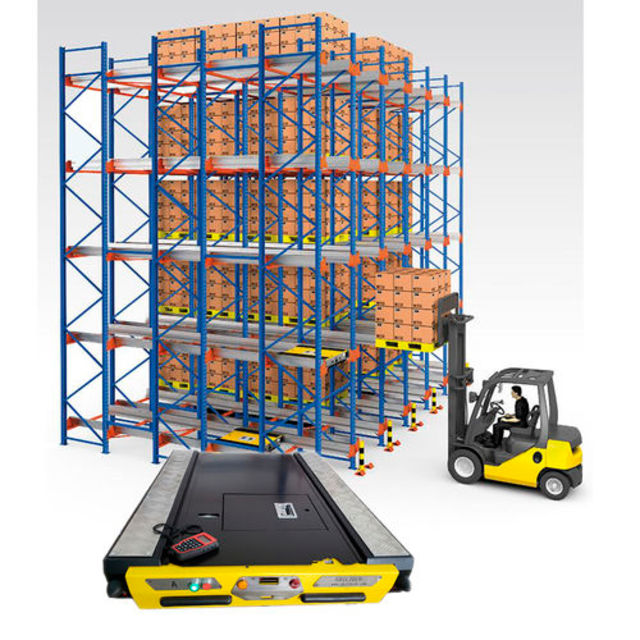

Shuttle racking is an automated storage system that uses a motorized shuttle to move loads within the racking channels. This system helps optimize space, speed up picking operations, and reduce manual intervention.

Key Features:

Automated Movement

→ The shuttle transports load units along the racking channels, eliminating the need for forklifts to enter the aisles.

Maximum Storage Density

→ The absence of aisles between pallet rows allows for optimal use of available space.

Increased Safety and Accuracy

→ The system reduces the risk of errors and product damage, improving operator safety.

Shuttle racking is particularly suitable for high-turnover warehouses, cold chain logistics, and companies handling large volumes of goods with intensive picking cycles.

Advantages of Shuttle Racking

Why Choose a Shuttle Racking System?

Integrating an automated shuttle into a warehouse provides numerous benefits in operational efficiency, speed, and space optimization.

Key Benefits:

Increased Storage Capacity

Removing aisles between racks allows for more load units to be stored in the same space.

Ideal for refrigerated or frozen environments, where every cubic meter saved translates into significant energy savings.

Speed and Automation

The shuttle autonomously moves pallets, reducing picking and storage times compared to traditional methods.

Loading and unloading operations are performed quickly and accurately.

Better FIFO and LIFO Management

The system supports both FIFO (First In, First Out) for products with expiration dates and LIFO (Last In, First Out)for non-perishable goods.

Lower Operational Costs

Less reliance on forklifts and reduced manual labor due to automation.

Optimized logistics resources lead to a more efficient supply chain.

Thanks to these benefits, shuttle racking is an ideal solution for high-density warehouses, e-commerce, cold chain logistics, and food distribution.

How to Integrate a Shuttle Racking System into Your Warehouse

Essential Steps for Effective Implementation

Analyze Business Needs

Evaluate workflow processes and storage requirements.

Determine whether FIFO or LIFO management is more suitable for your operations.

Racking System Design

Define the warehouse layout based on available space and load volume.

Select the number of shuttle required to ensure fast and continuous workflows.

Installation and Integration

Implement the racking and shuttle system along with Warehouse Management System (WMS) software.

Configure settings to optimize goods movement and workflow efficiency.

Operator Training

Employees must be trained to interact with the system and monitor operations using intuitive digital interfaces.

Maintenance and Upgrades

The system requires regular maintenance and software update to ensure long-term efficiency and reliability.

A well-integrated shuttle racking system enhances business productivity, reduces management costs, and ensures high operational efficiency.

FAQs

What is shuttle racking?

It is an automated storage system where a motorized shuttle moves load units within the racks, optimizing space and operational time.

Which industries benefit from this technology?

Shuttle racking is ideal for cold chain logistics, food, pharmaceuticals, e-commerce, and industrial warehouses that require fast and efficient storage management.

How safe is a shuttle racking system?

It is highly safe. It reduces the risk of accidents caused by forklifts and ensures more stable load handling, preventing product damage.

The automation of shuttle racking is a key innovation for companies looking to optimize storage space and speed up goods handling.

With greater storage capacity, reduced picking times, and high operational efficiency, this technology is the ideal choice for high-turnover sectors and advanced logistics.

Want to learn how to enhance your warehouse with shuttle racking? Contact us at: Unifreddo.it